Cov Hom Phiaj ntawm Stamping Parts

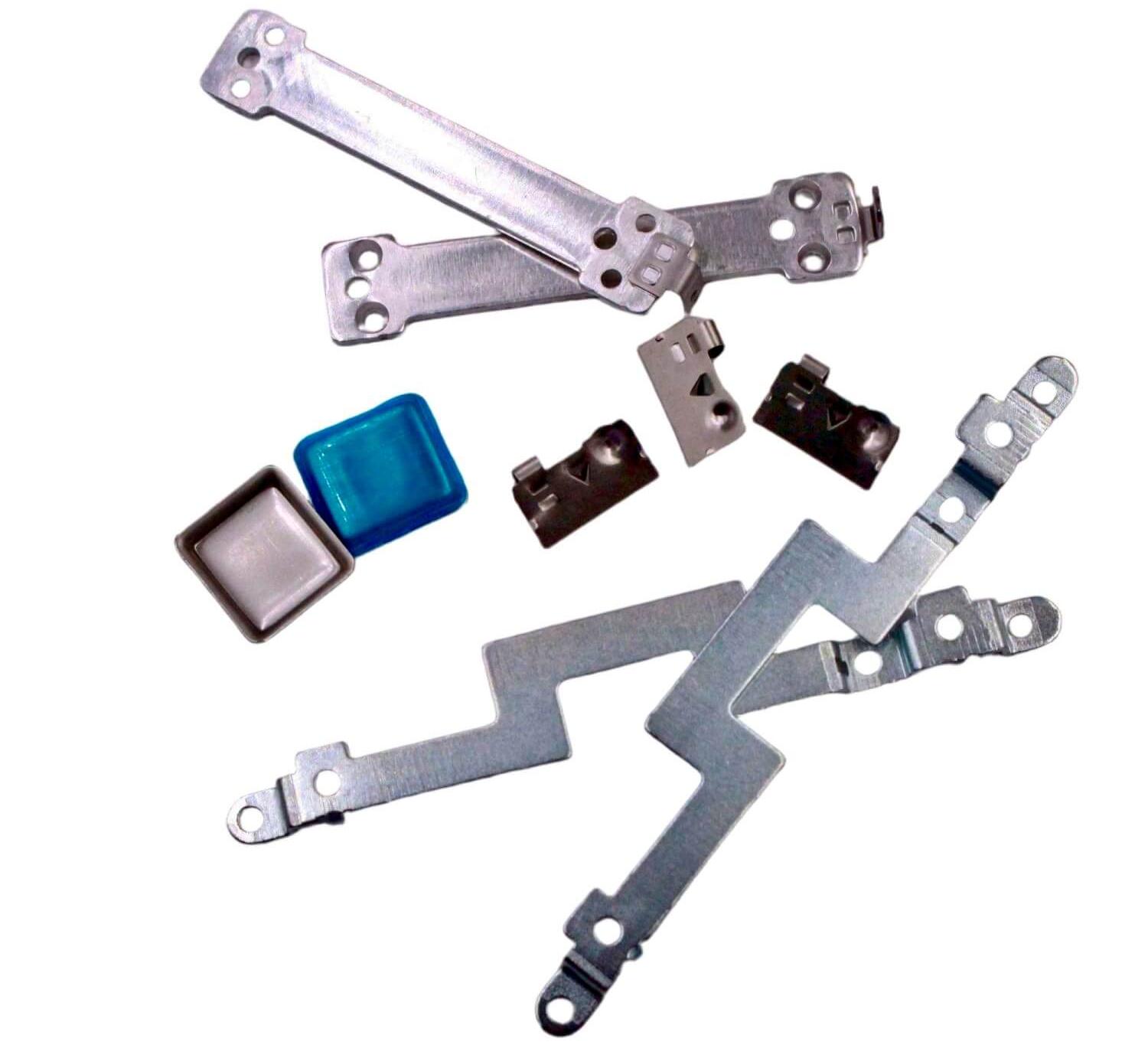

Cov khoom siv stamping yog tsim los rau qhov xav tau ntawm kev tsim khoom lag luam - qee qhov tuaj yeem haum rau qhov chaw sib dhos nyuaj, qee qhov tuaj yeem dais cov khoom siv ua haujlwm ruaj khov, thiab lwm tus tsuas yog ua tau raws li qhov yuav tsum tau txuas yooj yim. Cov no peb yog cov uas koj ntsib ntau zaus:

1. Cov Khoom Siv Hlau Tsis Muaj Hlau

Zoo tagnrho rau cov khoom uas xav tau tiv taus xeb lossis nyob twj ywm huv. Koj yuav pom lawv hauv:

•Cov cuab yeej kho mob thiab cov khoom siv (lawv ua tau raws li cov cai huv huv nruj heev)

•Cov tshuab ua zaub mov (sawv ntsug tiv taus dej thiab cov tshuaj ntxuav)

•Cov tshuab tso pa tawm hauv tsheb (kov cov cua sov siab yam tsis muaj xeb)

Cov khoom no kav ntev ntau xyoo, txawm tias nyob rau hauv cov xwm txheej hnyav.

2. Cov Khoom Siv Uas Muaj Cov Khoom Siv Aluminium

Zoo meej thaum koj xav tau ib yam khoom uas sib dua tab sis muaj zog—tsis muaj qhov hnyav ntxiv uas ua rau koj cov khoom hnyav. Feem ntau siv xws li:

• Cov khoom siv dav hlau (ua kom cov dav hlau thiab drones sib dua kom siv roj tau zoo dua)

• Cov vaj huam sib luag ntawm lub cev tsheb (muaj zog txaus rau kev siv txhua hnub, sib zog txaus los txhawb kev tsav tsheb)

•Cov thawv khoom siv hluav taws xob (xws li cov thav duab laptop lossis ntsiav tshuaj—zoo nkauj thiab ruaj khov)

Txhuas kuj tiv taus xeb, yog li nws ua haujlwm zoo ib yam li sab hauv tsev ib yam li nws ua sab nraud.

3. Cov Khoom Siv Tooj Liab Uas Muaj Cov Cim

Cov khoom siv uas xav tau hluav taws xob lossis cua sov zoo yog qhov xaiv zoo tshaj plaws. Lawv yog cov tseem ceeb hauv:

•Cov khoom siv hluav taws xob (xws li cov chaw nres nkoj USB lossis cov roj teeb—tsis muaj kev poob hluav taws xob)

•Cov cuab yeej hluav taws xob thiab cov transformers (ua kom cov tshuab hluav taws xob khiav tau zoo)

• Cov dab dej kub (ua kom CPU txias lossis teeb LED kom tiv thaiv kev kub dhau)

Koj tuaj yeem suav rau cov khoom no rau kev ua tau zoo tas li hauv cov khoom siv hluav taws xob thiab cov khoom siv fais fab.

Qhov khoom uas muaj cov cim zoo yuav ua rau koj cov khoom zoo lossis puas tsuaj. Peb muab cov khoom rau plaub lub lag luam loj:

1. Kev Tsim Khoom Siv Tsheb

•Cov Khoom Peb Ua: Cov ntsia hlau cav, cov khoom dai kom ruaj, cov tsev sensor, cov khoom siv hluav taws xob.

•Vim Li Cas Nws Tseem Ceeb: Peb cov khoom seem ua tau raws li cov qauv nruj uas lub tsheb xav tau—muaj zog txaus rau txoj kev tsis sib luag, meej txaus rau cov txheej txheem kev nyab xeeb, thiab pheej yig rau kev tsim khoom loj. Lawv pab ua kom cov tsheb muaj kev nyab xeeb dua thiab ua haujlwm tau zoo dua.

2. Khoom Siv Hluav Taws Xob & Kev Sib Txuas Lus

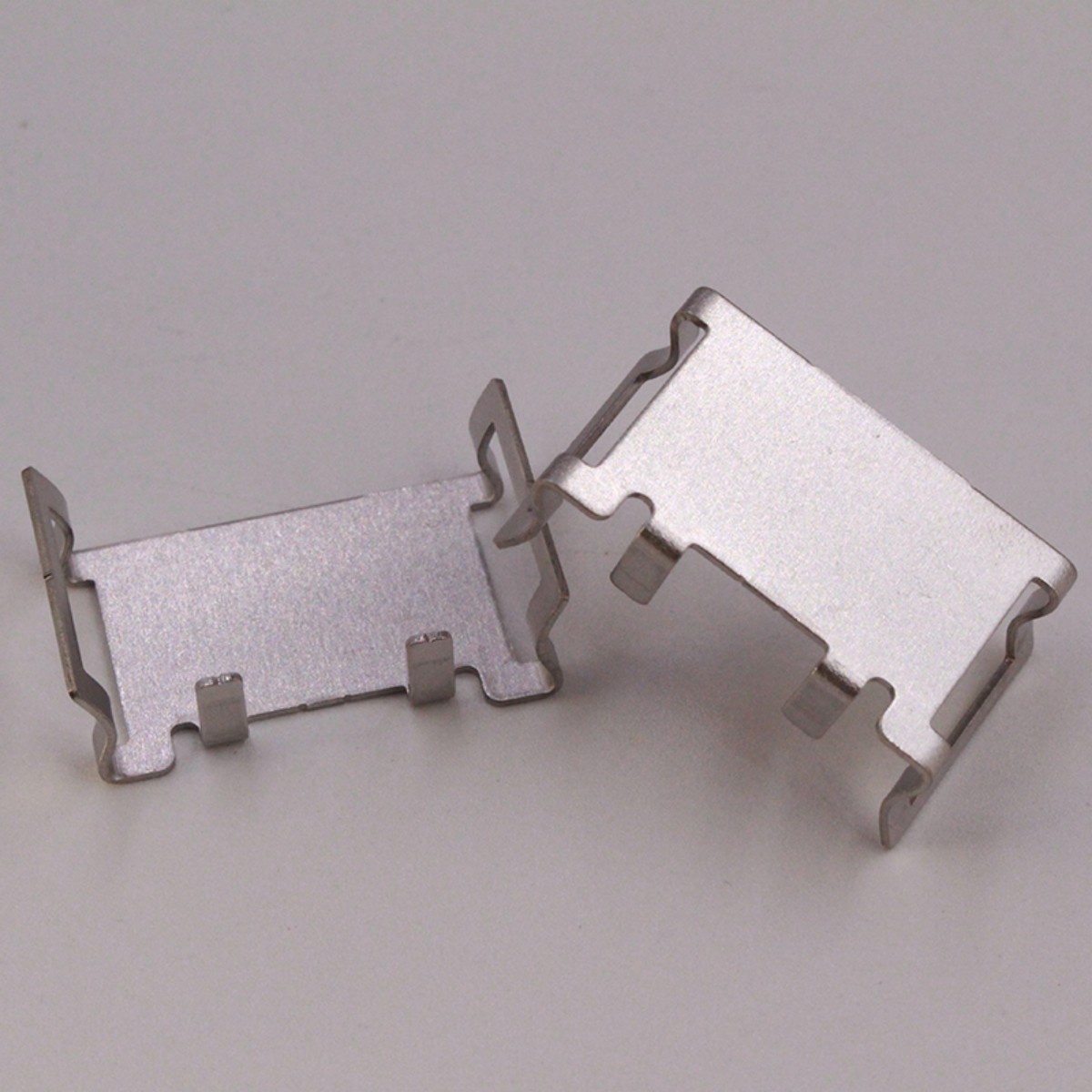

•Cov Khoom Peb Ua: Cov kaus poom tiv thaiv (thaiv kev cuam tshuam), cov xov hlau txuas, cov roj teeb sib txuas, cov khoom me me rau cov khoom hnav tau.

•Vim Li Cas Nws Tseem Ceeb: Cov khoom siv hluav taws xob xav tau cov khoom uas haum zoo kawg nkaus - peb cov stamping ntaus cov kev kam rau siab li ± 0.02 hli. Qhov ntawd txhais tau tias tsis muaj kev sib txuas xoob lossis cov khoom tawg hauv xov tooj, routers, lossis cov saib xyuas kev kho mob.

3. Cov Tshuab Siv Hauv Kev Lag Luam

• Cov Khoom Peb Ua: Kev laminations lub cev muaj zog, cov khoom gearbox, cov kev txhawb nqa cov qauv, cov hydraulic brackets.

•Vim Li Cas Nws Tseem Ceeb: Cov khoom siv hauv kev lag luam ua haujlwm hnyav - peb cov khoom siv tiv taus kev co, cov khoom hnyav, thiab kev siv tas li. Lawv ua rau cov siv conveyor, cov tshuab tsim kho, thiab cov neeg hlau khiav txhua hnub.

Yuav ua li cas los kho kom haum rau tus khub Stamping tshwj xeeb

Ntawm Yuhuang, peb tsis yog tsuas yog ua cov khoom xwb - peb pab koj tsim cov khoom zoo rau koj qhov project. Nov yog peb ua haujlwm li cas:

1. Xaiv Cov Hlau Zoo: Peb pab neeg yuav pab koj xaiv cov hlau tsis xeb, txhuas, tooj liab, lossis cov hlau sib xyaw tshwj xeeb. Peb yuav suav nrog lub zog, kev tiv taus xeb, tus nqi, thiab lwm yam kev xav tau uas koj qhov project muaj.

2. Kho Koj Tus Qauv: Qhia koj cov duab kos lossis lub tswv yim - peb yuav xyuas seb lawv puas yooj yim rau kev ntaus cim (qhov ntawd hu ua DFM kev tshuaj xyuas). Peb yuav qhia cov kev hloov me me kom ua rau qhov khoom muaj zog dua, pheej yig dua los tsim, lossis ua sai dua.

3. Ua Cov Khoom Kom Tseeb: Peb siv cov tshuab stamping (txij li 10-tuj txog 300-tuj) thiab cov cuab yeej tshwj xeeb los ua kom tau raws li koj qhov loj me. Txawm tias koj xav tau 10 daim qauv lossis 100,000 qhov, peb yuav ua kom tau raws li koj qhov kev txiav txim.

4. Ua tiav Txoj Haujlwm: Peb tuaj yeem ntxiv cov khoom ntxiv kom npaj tau siv - xws li plating (kom tiv thaiv xeb), kev kho cua sov (kom ua rau cov khoom tawv dua), lossis sib dhos (muab cov khoom sib dhos ua ke ua ib feem loj dua).

5. Tshawb Xyuas Qhov Zoo: Peb yeej tsis hla dhau qhov kev tshawb xyuas qhov zoo. Peb siv cov cuab yeej xws li CMM tshuab (los ntsuas cov ntsiab lus me me) thiab cov khoom sib piv optical (los xyuas cov duab) kom paub tseeb tias txhua qhov yog. Peb ua raws li ISO 9001 thiab IATF 16949 cov qauv - yog li koj paub tias koj tau txais qhov zoo sib xws.

Cov Lus Nug Feem Ntau

Q: Vim li cas ho xaiv hlau stamping dua li machining?

A: Kev luam ntawv sai dua thiab pheej yig dua thaum koj xav tau ntau qhov chaw. Nws nkim hlau tsawg dua, thiab koj tuaj yeem ua cov duab nyuaj uas yuav raug nqi ntau heev nrog kev siv tshuab. Ntxiv mus, txhua qhov tawm los zoo ib yam - tsis muaj qhov tsis sib xws.

Q: Koj xav tau cov ntaub ntawv hom twg rau kev hais nqe?

A: PDF, DWG (2D kos duab) lossis STEP, IGES (3D qauv) ua haujlwm zoo tshaj plaws. Tsuas yog suav nrog cov ntsiab lus xws li hom hlau, tuab, qhov ntev, qhov tiav ntawm qhov chaw, thiab pes tsawg qhov koj xav tau.

Q: Koj puas tuaj yeem ua cov khoom nrog kev kam rau siab heev (zoo li ± 0.01 hli)?

A: Yog. Nrog peb cov tshuab nias thiab cov cuab yeej ua haujlwm raug, peb tuaj yeem ntaus ± 0.01 hli rau cov khoom me me. Peb yuav tham txog koj cov kev xav tau ua ntej kom paub tseeb tias nws ua tau.

Q: Nws siv sijhawm ntev npaum li cas thiaj li tau txais cov khoom seem?

A: Cov qauv (siv cov cuab yeej uas twb muaj lawm) siv sijhawm 1-2 lub lis piam. Rau cov cuab yeej tshwj xeeb thiab cov xaj loj, nws yog 4-8 lub lis piam. Peb yuav muab sijhawm meej rau koj thaum peb lees paub koj qhov kev txiav txim.

Q: Koj puas ua cov qauv ua ntej tag nrho cov khoom tsim tawm?

A: Muaj tseeb tiag. Peb mam ua ob peb daim qauv ua ntej kom koj tuaj yeem xyuas seb lawv puas haum thiab ua haujlwm tau. Nws yog ib txoj hauv kev zoo los kho cov teeb meem thaum ntxov - txuag lub sijhawm thiab nyiaj txiag tom qab.

Cov ntsia hlau

Cov ntsia hlau Cov txiv ntoo

Cov txiv ntoo Cov Ntxuam

Cov Ntxuam Caij nplooj ntoos hlav

Caij nplooj ntoos hlav